What to Anticipate From Quality Commercial Refrigerator Repair Solutions

What to Anticipate From Quality Commercial Refrigerator Repair Solutions

Blog Article

The Ultimate Overview to Commercial Refrigeration Fixing: Usual issues and vital actions Explained

Typical Commercial Refrigeration Concerns

When operating industrial refrigeration systems, organizations may run into several common issues that can affect the effectiveness and performance of the equipment. Varying temperature levels within the refrigeration device can lead to food perishing, boosted energy usage, and endangered quality and safety and security criteria.

One more common issue is refrigerant leakages. Leaks can arise from wear and tear, poor setup, or manufacturing issues. Low refrigerant degrees not just prevent the device's cooling capability yet can likewise cause compressor failure if left unaddressed.

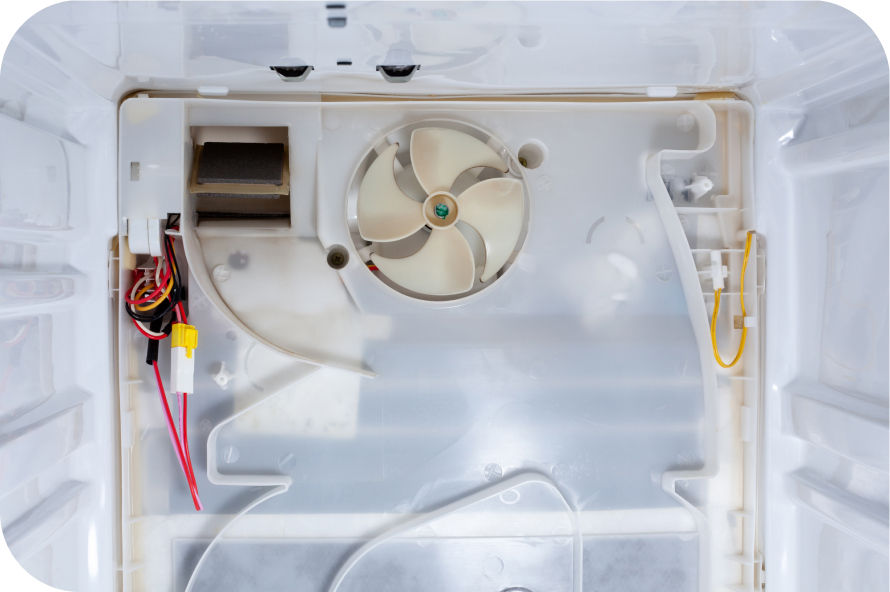

In addition, ice accumulation on evaporator coils is a regular worry. Ice build-up restricts air movement, creating the device to work more difficult and consume more power. Normal cleansing and maintenance of the coils can aid avoid this problem.

Crucial Tools for Fixing Refrigeration Devices

Using the appropriate devices is crucial for effectively fixing commercial refrigeration units to make sure optimum performance and long life. Amongst the fundamental devices required are manifold assesses for examining cooling agent stress, refrigeration wrenches for tightening up or loosening up fittings, a multimeter for screening electric parts, and leakage detection devices such as digital leakage detectors or ultraviolet dye kits.

In the realm of specialized tools, tube cutters and flaring tools are important for dealing with copper tubes, while a recuperation device is required for safely eliminating refrigerants. A temperature level weapon can be beneficial for rapidly recognizing temperature level differentials within the device. Purchasing top notch devices not just boosts efficiency during repairs yet also adds to the precision and dependability of the upkeep work executed on business refrigeration devices.

Step-by-Step Troubleshooting Overview

The following step is to test the temperature level controls and setups to guarantee they are functioning correctly. This consists of checking the thermostat, defrost timer, and other control mechanisms to verify that they are regulating the temperature as meant. If any kind of discrepancies are discovered, modifications or substitutes might be required. commercial refrigerator repair.

Ultimately, the technician needs to examine the condenser and evaporator coils for dust or particles buildup, which can hamper correct cooling. Cleansing these elements can frequently deal with problems with temperature policy and efficiency.

Preventative Upkeep Strategies

Implementing routine preventative maintenance measures is important for ensuring the longevity and optimum efficiency of commercial refrigeration systems. By adhering to a proactive maintenance timetable, businesses can minimize the threat of costly failures, protect against downtime, and prolong the lifespan of their refrigeration tools.

One essential preventative upkeep technique is routine cleansing of condenser coils. Gradually, these coils can collect dust, particles, and dust, which can hinder heat transfer and decrease the system's effectiveness. By cleansing the why not try these out coils regularly, organizations can ensure that the refrigeration system operates at peak efficiency.

In addition, examining and replacing worn gaskets on doors is an additional vital upkeep task. Damaged gaskets can lead to air leakages, causing the refrigeration system to work more difficult to keep the wanted temperature. By replacing damaged gaskets without delay, services can improve power effectiveness and prolong the life of the equipment.

Integrating these preventative upkeep techniques into an extensive upkeep plan can aid services enhance the performance and integrity of their industrial refrigeration systems.

Expert Repair Vs. DO IT YOURSELF: Benefits And Drawbacks

Engaging a specialist repair solution for commercial refrigeration systems uses unique benefits over trying do it yourself fixings. Industrial refrigeration devices are intricate systems that require specialized understanding and skills to diagnose and fix properly. Professionals have the training and experience to identify issues precisely, resulting in quicker and much more accurate fixings. They additionally have accessibility to sophisticated devices and equipment that might not be readily available to the typical individual.

Moreover, expert repair service services often provide guarantees on their work, providing you comfort understanding that the task is assured. Trying to fix a commercial refrigeration system yourself can bring about additional damages otherwise done properly, potentially leading to even more pricey repair work down the line. Furthermore, DIY repair work may void any kind of existing service warranties on the equipment, leaving you only in charge of any kind of future problems that might emerge. While DIY repair work might seem economical initially, the long-term advantages of expert repair solutions outweigh the unpredictabilities and risks related to attempting fixings by yourself.

Conclusion

Finally, comprehending typical industrial refrigeration issues, having the vital tools for repair work, following a step-by-step troubleshooting guide, and applying preventative maintenance techniques are vital elements of preserving and repairing business refrigeration systems. While professional repair solutions might supply proficiency and performance, do it yourself repairs can also be a cost-efficient choice for those with the essential skills and knowledge. Ultimately, normal maintenance and timely repair services are essential for making sure the correct functioning of business refrigeration units.

Understanding the vital steps for industrial refrigeration repair and being able to recognize typical issues are critical skills for any type of business proprietor or maintenance personnel. In this thorough overview, we will certainly explore the fundamental steps navigate to these guys and common problems in commercial refrigeration repair, furnishing you with the expertise required find more information to attend to these obstacles effectively.

Engaging a professional repair solution for industrial refrigeration systems offers distinctive advantages over attempting DIY repairs. Attempting to repair a business refrigeration system on your own can lead to more damage if not done appropriately, potentially resulting in even more costly fixings down the line.In verdict, understanding common business refrigeration problems, having the essential tools for fixing, following a detailed troubleshooting guide, and carrying out preventative maintenance strategies are vital elements of preserving and fixing commercial refrigeration units.

Report this page